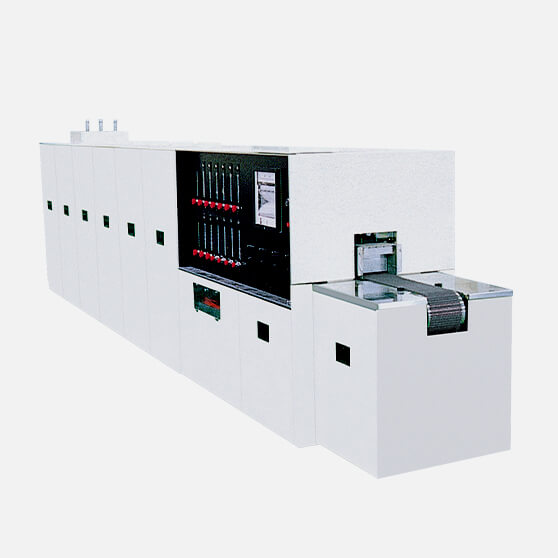

Mesh Belt Type Continuous Furnace Multi-Inlet/Exhaust Type

Specifications

| Max. operating temperature | 1150°C |

|---|---|

| Transport system | Mesh belt transport |

| Heating chamber | Heat-resistant steel muffle |

| Supported belt widths (mm) | 150 to 800 |

| Supported atmospheres | N2, N2 (wet), N2+air, air |

| Applications |

|